DI HAI MACHINERY

- …

DI HAI MACHINERY

- …

1-50 t/h Dry Mortar Plant

Di Hai is your best dry mortar plant manufacturer in China.

Simple Dry Mix Mortar Production Line

- On the basis of dry mortar mixer, screw conveyor, finished product hopper, simple dust collector and a fully automatic valve packaging machine are added.

- A three-layer dry mortar paddle mixer is used, the mixing time is 10-15 minutes per batch, and 24 hours of uninterrupted work is possible.

- The height of this simple dry mortar production line is no more than 4 meters, with a small footprint and small investment. This is a simple and practical production line.

Improved Dry Mortar Production Line

This improved dry mortar production line workshop occupies 100m2, and the equipment occupies 20 m2, the height of the equipment is 4.2m, it needs 2-3 people to operate the machine, 1000kg for one batch.

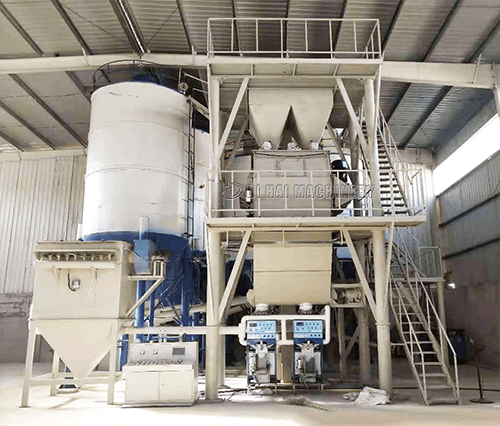

10-30 T/H Dry Mortar Mix Plant

- Manufacture of dry mortar that can meet different requirements, such as masonry mortar, plastering mortar, thermal insulation mortar, self-leveling mortar, etc.

- High degree of full automation, automatic feeding, automatic mixing, automatic unloading, only one person can complete the operation of the whole set of dry mortar mix plant, saving manpower and material resources, green and environmental protection.

More than 30T/H Dry Mix Mortar Plant Manufacturer

- Adopt double shaft gravityless dry mortar mixer machine, dust will never enter the bearing, and the practical life is long.

- If your sand moisture content is more than 5%, you can also configure a sand drying line.

- Adopting cloth bag dust collector, collecting dust efficiently, environmental protection.

- PLC controls this assembly line, fully automated operation, you can also choose automatic palletizer, save labor costs, improve production efficiency.

Di Hai Cases & Solutions of Dry Mortar Plant

The following are the real cases of our dry mix mortar production line. Whether it is a small dry mortar production line or a fully automatic dry mortar plant, each production line carries the mission of making money. If you see the dry mortar plant site you are interested in, please click on the picture to view details, you can also contact us for a quote.

Dry Mix Mortar Production Line in Malaysia

Dry Mortar Plant With Sand Dryer in Honduras

Gypsum Dry Mortar Plant

Dry Mortar Production Line in Malawi

Dry Mortar Plant in Australia

Dry Mortar Mixer Machine

Dry Mortar Production Line in Zimbabwe

Dry Mix Mortar Plant in Russia

Whole Process of Dry Mortar Plant

Dry Mix Mortar Plant Manufacturer

Di Hai is your best dry mortar plant manufacturer in China. Let us build your own dry mortar plant.

Will introduce dry mix mortar plant in detail from the following items

If you have more question of dry mix mortar production line, feel free to contact us.

1What is?

2Application

3Components

4Advantages

5Drawing

6Costs

7How to choose

8Suggestions to bosses

- 1. What's Dry Mortar?

Simply speaking, the dry mortar is a ready mixed mortar, with cement as the main material, according to different requirements, add different additives, for example: If you need ceramic tile adhesive, add tile adhesive in the mortar. In order to facilitate transportation, the dry mortar is usually delivered to the construction site in bags. When using, just add water and mixing evenly, then you can use it directly.

Regarding the formulation of dry mortars, here are some points to summarize:

- It is easy to formulate a formula that meets the standard, if you do not consider the cost!

- A good formula requires good workability. If the workability is not good, the performance of the mortar cannot be fully exerted;

- The formula needs to have good adaptability, the environment of the construction site is different, and a good formula needs to be adjusted according to different seasons;

- Reasonable price, reducing cost is not a sacrifice of product performance

- A good formula needs to be simple. Any kind of material has advantages and disadvantages. It is not a necessary raw material. Try not to add it, which can make production simple and reduce costs;

- A good formula must have a certain insurance factor and do not blindly reduce costs, because there is a certain gap between experiment and actual production and construction on site.

2. Application of Dry Mortar Production Line

What dry mortars can produce by dry mix mortar machine?

So much of the mortar below is produced by dry mortar plant. Is there any mortar you need?

1. Masonry mortar for bricks, stones and other blocks.- This mortar bonding is strong.

- Masonry mortar has strong plasticity and low shrinkage, which can ensure the stability of the mortar to the greatest extent.

2. Plastering mortar applied on the surface of buildings or building components.

- Strong ability to withstand external action.

- It has sufficient resistance to water flushing. If you want to use plastering in the bathroom or other damp rooms, it is a very good choice.

- Reduce the number of plastering layers and improve work efficiency.

- The plastering mortar is easy to smooth, and the surface is smooth and even.

- The fluidity of the plastering mortar is good, your construction becomes easier.

- The water retention of plastering mortar is very good, even after you use it for a long time, it is not easy to crack.

3. Tile adhesives are mainly used to paste decorative materials such as tiles or floor tiles.

- The bonding ability of the tile adhesive is very strong, which can effectively reduce delamination, peeling, avoid hollowing, cracking, etc.

- Protect the environment without toxic additives.

4. Thermal insulation mortar is a common building material. It can be used on the surface of buildings to form a thermal insulation layer and play a certain role in thermal insulation.

- It can be used after adding water, easy and quickly.

- Thermal insulation mortar has stable performance, low shrinkage, and can effectively prevent mortar cracking.

- It is no problem if the construction is on a wet base.

- The thermal insulation effect of the thermal insulation mortar is very good, and it is very environmentally friendly.

5. Tile grout is used to grouting walls or floors between tiles.

- Good adhesion to the edge of the tile

- Low shrinkage rate, reduce crack formation

- Low water absorption and strong resistance to penetration

- It has excellent constructability

6. Decorative mortar is a kind of mortar that can directly decorate buildings without smooth base or other decorative treatment, and can replace paint or tiles.

- The colors of decorative mortar are natural and various.

- Lower cost and high cost performance.

- Convenient construction and easy operation.

- Material safety and environmental protection.

- Strong adhesion, low water absorption and good air permeability.

7. Self-leveling mortar is used for leveling the base of various floor materials.

- No segregation, the mortar has good fluidity and can be leveled automatically within a certain thickness.

- The self-leveling time is short, and it can dry in a short time.

- According to your requirements, the formulation can be adjusted to change the bearing capacity of the mortar.

- Strong adhesion, not easy to layer, not easy to empty.

- Low shrinkage, environmentally friendly materials.

8. Wall putty mortar used for building coating base leveling.

- Save paint usage and reduce project cost

- Has strong adhesion and flexibility

- Aging resistance, impermeability and moisture resistance

- Environmental protection, non-toxic and safe

- Good crack resistance and breathability

Advantages of internal wall plaster putty:

- Strong adhesion

- Good surface decoration

- Fireproof

- Insulation

- Save time

- Easy construction

- with breathing function

9. Gypsum joint mortar used for joints of thin plate keel systems such as paper surface gypsum board and cement fiber board.

- Non-toxic five flavors, belonging to green building materials

- No cracking, high strength

- Fine and smooth texture, easy to polish

- It has good crack resistance, easy to stir, easy to operate, fast drying speed, good bonding effect.

3. Main parts of dry mix mortar plant

A full automatic dry mortar plant consists of double shaft dry mortar mixer, weighing batching system, dust collector system, conveying system, aggregate storing system, control system, powder filling machine etc.

Double Shaft Gravity-free Paddle dry mortar mixer:

- The dry mortar mixer can fully mix the materials, with uniformity of up to 99.8%,and the mixing time is 30-60s per batch.

- The blades inside the mixer are bolted, in order to prevent maintenance and replacement in the future

- A cleaning door is set at the bottom to ensure that there is no residue when discharge.

- Tight seal, no dust leakage, at the same time, the dry powder will never enter the bearing, increasing the service life of the bearing.

- Applicable to various physical property materials with different density, granularity, shape, etc.

According to your actual material characteristics, you can also choose, ribbon mixer, plough mixer, real stone paint mixer.

Di Hai Machinery developed and designed other dry mortar mixer machines, such as high speed dispersion machine (liquid material mixer machine).`Mobile Detachable Cement Silo

- The bolted cement silo consists of tank, top cover, cone, landing leg, arch breaker, electric vibrator, pneumatic valve, dust collector, etc.

- We supply cement silo from 30 ton to 1000 ton, and also supply customize difference cement silo according to customer demands.

- The big advantage of bolted cement silo is detachable and easy to install. The detachable cement silo is very saving space, save the shipping cost, and we have the installation video ready for you, you just install cement silo step by step.

- Generally speaking, the discharging height is 1.5m, if you have special required, we can customize the discharge heigh according to your requirements. Lining leg heigh depends on discharging height.

- There is two dust collector, common dust collector, and electric dust collector.

PLC Control System

We equip computer control and PLC control system to control the machines, it can realize automatic control and touch screen operating for dry mortar plant.

Full automatic dry mortar valve ton bag packing machine

- Weighing Scope: 5~50kg, adjustable on the panel.

- Discharge Port Qty.: 1 pic or 2 pcs

- Motor Power: 3kw

- Weighing device: Automatically

- Air Requirements: 0.4-0.8MPa ( dry compressed air)

- weighing data can be adjusted according to the bag’s specifications.

- It can fully fill one 25kg bags within 3-5s

- Advantage: use the computer for weighting, a small error, fastpacking speed, save time and effort.

Packaging system: according to your project's production capacity, your market, customer preference, you can choose the bagging system, bulk system, fully automatic palletizing system.

- 4. Advantages of dry mix mortar plant

- Excellent mixing performance with high efficiency and high productivity

- Environment protection by dust collection system and anti-noise design

- Easy to operation

- Convenient structures for disassembly

- Super property and low production cost;

- Less space demand;

- Full -automatic electric operation with PLC/PC control;

- Electrical weighing system

- 5. Design & Drawing for dry mortar plant

You are special, Di Hai engineer will design and drawings for you according to your site, layout planning, your preferences, material characteristics and your budget, until you are satisfied. Of course, Dihai's engineers will propose the most professional turnkey solution for you based on years of experience.

6. How about dry mortar mixing plant cost?

Meeting your needs is the ultimate goal of Di Hai Machinery. Di Hai will combine your actual situation, such as your area, what kind of mortar is needed, and how much output is needed? What is your budget, we give you what Di Hai think is the most perfect plan. Di Hai dry mortar plant manufacturer, design every detail of dry mortar plant for you, and save you every cost.

In short, the cost of dry mix mortar production line with small output is low price, and the cost of dry mix mortar plant with large output is high price; the cost of simple dry mix concrete plant is low price, and the cost of automated dry mix plant is high price.

- 7. How to choose dry mix mortar plant according to your capacity?

When you import dry mortar plant from China, will you also consider this question: "How should I choose dry mortar machine, what issues need to pay attention to?"

Di Hai Machinery provides turnkey solutions for you who need to import dry mortar plant from China.

1. If you have just been in the business of dry mix mortar plant, you are very optimistic about the prospects of dry mortar production lines, and have done market research in your country. The engineers of Di Hai suggest that you choose 1-8t/ h small capacity dry mix mortar production line.

2. If you already have a small dry mix mortar production line, or you have enough budget, and now want to expand the output of dry mortar production line, then choose the semi-automatic or automatic line of dry mortar plant, it can bring you 10-20t / h Yield.

3. If you have a mine or you have sufficient resources, you want to build a completely dry mortar plant, the output more than 30t / h, at the same time, you can increase the sand drying line according to your needs. - 8. Service for dry mix mortar plant

- Well-trained and experienced staff to answer all your inquiries.

- We will send our professional engineers to your country and help install the plant, train your worker to operate the plant.

- OEM & ODM are welcome. OEM brand is available.

- If you have any idea or demand, we can provide the customization service.

- Protection of your market area, ideas of design and all your private information.

- We will supply the spare parts to ensure the quality of our plant.

- Your inquiry will be replied within 24 hours.

- Provide following up after-sales services. We will dispatch our serviceman to solve the problem for you if you have questions about our plant.

- 9. As a beginner in dry mortar plant, what should I pay attention to?

- Investigate the market demand for ready dry mix mortar in your country and your location; after market research, determine the finished dry mixing mortar you want to produce.

- Determine the scale of a dry mortar plant based on your budget and the results of market research. Determine the type of product mortar and determine the scale of dry mortar production line;

- If you want to import dry mortar plant from China, it is recommended that you come to China in person to visit the manufacturer of dry mortar equipment and choose a few more dry mix mortar suppliers, preferably 2-3 suppliers, to confirm whether he is Real factory, factory-scale, recent dry mortar plant case.

- If the manufacturer of the dry mortar plant has an on-site case, you can go to the dry mortar production line site and pay attention to the details. You will find many unexpected details, which are very helpful for you to purchase dry mortar plant and produce dry mortars.

- After visiting the dry mix mortar factory, determine the preliminary plan, and let the suppliers design 3D drawings for you based on the actual site situation.

- After-sales service is also very important. If you choose a fully automatic line, then when signing the contract, you must agree on later installation issues, such as: Will you send an installer to install dry mix mortar plant in our country? How is your installer technology? Can you train our employees on the operation of dry mortar plant? Is it free for engineers to install in our country? If it is a charge, what is the standard of the charge?

- 10. How to choose a reducer when importing dry mortar plants from China?

- One of the important criteria for choosing a dry mix mortar production line is the reducer.

- At present, the reducers used in the dry mortar machines mainly include planetary cycloid reducer and gear worm gear reducer

- These two reducers have the function of reducing the speed and increasing the torque, but the working principles of the two reducers are different, and the price difference is also very large.

- Planetary cycloid reducer, using the principle of planetary transmission, using cycloid pinwheel meshing, advanced design, novel structure of reduction mechanism, large transmission ratio, high efficiency, small size, lightweight, stable operation, low maintenance rate But the price is slightly higher.

- The gear reducer uses the principle that the gears mesh with each other, which is large in size, easy to install, and high in carrying capacity, but the price is low.

- Di Hai Machinery's dry mortar plant mainly uses planetary cycloid reducer, the cost is slightly higher, but the maintenance rate is low, the overload capacity is strong, and frequent start and stop can also ensure normal work.

- Di Hai Machinery has 15 years of experience in the production of dry mortar plant. Here I remind you not to ignore the quality of dry mortar machines for the sake of cheap prices.

How to choose dry mortar mixer?

- The test report can intuitively verify the quality of the dry mortar mixer.

- If the dry mortar mixer manufacturer cannot provide the test report such as CE, then the dry mortar mixer is most likely to be out of quality.

- The dry mortar mixer can be seen by observing its workmanship, welding process, materials, and the original electric components used.

- Good dry mortar mixer manufacturers have thick steel plates, smooth weld seams, rigorous sealing, and good anti-rust treatment on the surface, copper core motors and cycloid reducers are used.

- The thickness of the dry mortar mixer steel plate and the thickness of the mixer blade directly affect the quality and service life of the dry mortar mixer.

Contact Di Hai Service Engineer Team

Dry Mix Mortar Plant Will Boom Your Project!

Contact

Tel: +86 15890626237

Email:

manager@

WeChat:

15890626237

WhatsApp:

+86 15890626237

Di Hai Machinery Co.Ltd © 2021. Privacy Policy